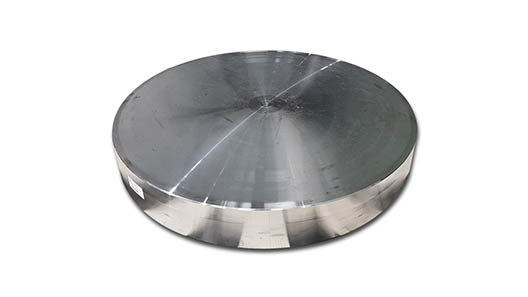

Stainless Steel 317L Forged Blocks

Stainless Steel 317L is one of the most sought-after materials in various industries. Known for its excellent resistance to corrosion, strength, and durability, this alloy is used in a range of applications, from chemical processing to marine environments. Ferrobend, a leading manufacturer of forged stainless steel components, plays a crucial role in producing Stainless Steel 317L forged blocks that meet the highest industry standards. In this article, we will explore the features, benefits, applications, and manufacturing process of these high-quality forged blocks. Stainless Steel 317L forged blocks are widely considered to be one of the most reliable and durable solutions for demanding environments.

Stainless Steel 317L is a low-carbon variant of the standard 317 stainless steel alloy. The composition of 317L includes significant amounts of molybdenum (3-4%), which enhances its resistance to pitting and crevice corrosion, particularly in harsh environments. The low carbon content in 317L ensures that the alloy retains its resistance to carbide precipitation during welding, making it an ideal choice for welded constructions that demand both strength and corrosion resistance.

Forging, in particular, is a process that improves the structural integrity of the material, making it stronger and more resilient compared to other methods of manufacturing. The forging process involves heating the material and shaping it under pressure, which refines the grain structure, making the final product stronger and more durable than other forms of steel. Due to the presence of molybdenum and low carbon content, 317L stainless steel has exceptional resistance to a variety of corrosive agents, including sulfuric acid, chloride solutions, and seawater. The forging process further optimizes the alloy's resistance to corrosive damage.

Ferrobend is known for its cutting-edge forging techniques and commitment to producing high-quality forged stainless steel components. The manufacturing process at Ferrobend is highly controlled and follows industry best practices to ensure that every Stainless Steel 317L forged block is produced to perfection.

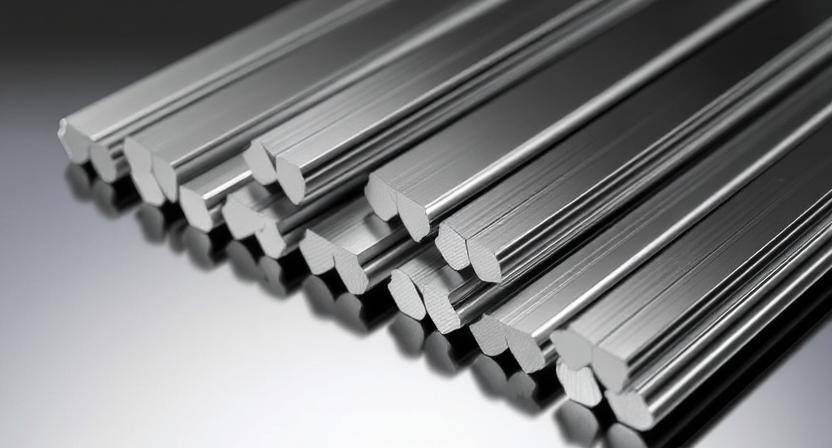

Ferrobend begins the process by sourcing high-quality Stainless Steel 317L billets from reputable suppliers. The raw material undergoes rigorous inspection and testing to ensure it meets the required chemical composition and physical properties before being used in the forging process. Once the billets are selected, they are heated to an optimal forging temperature. The material is carefully heated to ensure uniform temperature distribution. This heating process softens the steel, making it more malleable and easier to shape during the forging process.